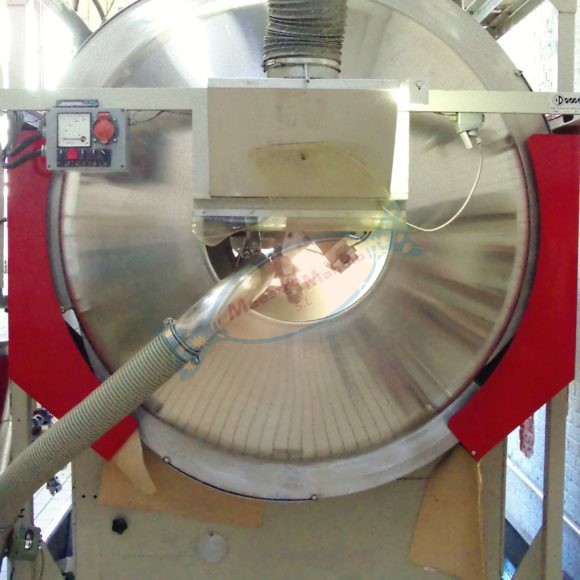

Dumoulin Ida 500 automatical coater

Complete Dumoulin model IDA 500 coating system with all in one , air handling equipment , syrup cooker with syrup tanks , spray system with nozzless and guns and electrical pannel , all manufactured year 2004 .More info below :

Automatic coating drum

– Syrup storage and distribution system

• volume150L (diameter 600mm x height 600mm)

• electrical power: 4kW (2 heaters for the double jacket + 1 circulation pump + 1 pump for the syrup)

• dimensions Length 1200 x depth 800 x height 1300mm

– Coating drum:

* capacity: 200-500 kg batch

* can work with dry fruits (almonds, hazelnuts, …), chocolat kernels, cereal balls, …

* suitable for sirup coating (hard or soft coating). Must be adapted for chocolate coating (spraying nozzles, perforated drum)

* cylinder diameter 1400mm x length 2350mm, opening for access: diameter 550mm

* perforated stainless steel drum, equipped with baffles,

* ramp with spray nozzles and washing system to avoid crystallisation of the nozzles between two cycles. Ramp mounted on a rail for maintenance

* external and internal air boxes to blow dry air and suck humid air (to be connected with an air production unit)

* programmable rotation speed (4KW motor)

* peripheral openings for drum emptying by slow rotation of the drum

* retractable conveyor with removable panels to collect finished products and bring them in the front of the machine

* dimensions of the drum: Length 3000 x width 1900 x height 2450mm

– Control system

* SIEMENS PLC for automatic or manual operation of the system

* adjustable cycle parameters

– spraying time,

– time and speed of rotation during spraying / mixing,

– time and speed of rotation during drying cycle

– choice of wind tunnels (internal / external / internal and external)

* size of the electrical cabinet: Length 800 x depth 600 x height 2300mm

– air / dust collector

* cyclone diameter 700mm, height 2200mm (3KW motor)

* cylindrical textile filters mounted in a frame Length 1100 x Depth 700 x Height 2000mm

the filters must be changed (12 pieces)

– energy: compressed air + electricity (three-phase 400V 12 kW) + water (washing the nozzles)

– peripherals (to be added to the installation so that it is complete and operational):

dry air production system (hot or cold depending on the type of coating)

Complete Dumoulin model IDA 500 coating system with all in one , air handling equipment , syrup cooker with syrup tanks , spray system with nozzless and guns and electrical pannel , all manufactured year 2004 .More info below :

Automatic coating drum

– Syrup storage and distribution system

• volume150L (diameter 600mm x height 600mm)

• electrical power: 4kW (2 heaters for the double jacket + 1 circulation pump + 1 pump for the syrup)

• dimensions Length 1200 x depth 800 x height 1300mm

– Coating drum:

* capacity: 200-500 kg batch

* can work with dry fruits (almonds, hazelnuts, …), chocolat kernels, cereal balls, …

* suitable for sirup coating (hard or soft coating). Must be adapted for chocolate coating (spraying nozzles, perforated drum)

* cylinder diameter 1400mm x length 2350mm, opening for access: diameter 550mm

* perforated stainless steel drum, equipped with baffles,

* ramp with spray nozzles and washing system to avoid crystallisation of the nozzles between two cycles. Ramp mounted on a rail for maintenance

* external and internal air boxes to blow dry air and suck humid air (to be connected with an air production unit)

* programmable rotation speed (4KW motor)

* peripheral openings for drum emptying by slow rotation of the drum

* retractable conveyor with removable panels to collect finished products and bring them in the front of the machine

* dimensions of the drum: Length 3000 x width 1900 x height 2450mm

– Control system

* SIEMENS PLC for automatic or manual operation of the system

* adjustable cycle parameters

– spraying time,

– time and speed of rotation during spraying / mixing,

– time and speed of rotation during drying cycle

– choice of wind tunnels (internal / external / internal and external)

* size of the electrical cabinet: Length 800 x depth 600 x height 2300mm

– air / dust collector

* cyclone diameter 700mm, height 2200mm (3KW motor)

* cylindrical textile filters mounted in a frame Length 1100 x Depth 700 x Height 2000mm

the filters must be changed (12 pieces)

– energy: compressed air + electricity (three-phase 400V 12 kW) + water (washing the nozzles)

– peripherals (to be added to the installation so that it is complete and operational):

dry air production system (hot or cold depending on the type of coating)

Español

Español